Machine stress-grading uses a machine to bend each piece of timber (generally about its minor axis). The machine measures the stiffness of the piece and uses a loose correlation between stiffness and strength to assign a stress grade. A sorted group with a small range of E (stiffness) can produce a larger range of strength. The E value is also used to infer all of the other structural properties, including tension, compression and shear strength . A review of the process is discussed in the presentation available for download below.

Machine stress-grading leads to the classification of timber on the basis of structural properties, and the different groups are directly given either F-grades or In-grade structural properties, which are appropriate for the whole parcel of graded timber. Machine stress-grading is often perceived as more objective and efficient than visual grading methods.

In Australia, most locally grown exotic softwoods (such as radiata pine) are currently graded this way. New Zealand grown radiata pine and some imported North American species such as Douglas fir or the mixed species SPF and hem-fir can also be graded mechanically. Limited machine stress grading is also used in Europe on spruce and pine species.

Modern grading machines are computer controlled and record-grading data, generally assigning a grade to the whole piece based on the minimum modulus of elasticity measured in the length of the piece. The grade is assigned by the machine and marked on each piece, automatically. Qualified graders visually check each piece and can override the machine to downgrade a piece of timber if necessary. Visual overrides are required after the timber has passed through the grading machine to check the ends of each piece. (The machine cannot check the stiffness of the metre of timber at each end.) In some cases, knot size limits in the whole piece are also required to ensure satisfactory strength.

Machine grading is a single step operation - the machine output is a stress grade (for instance an F-grade or an MGP grade) rather than a structural grade, which has to be converted to a stress grade on the basis of species, as is the case for visual grading.

In many respects, machine stress grading produces better separation of the grades, with less overlap of stiffness between adjacent grades. However, the correlation between the measured parameter and other properties is not particularly good. This still gives a significant overlap between the strength properties of different grades of machine stress-graded timber.

Some structural grades can only be assigned by machine stress grading. MGP grades can only be given to Australian pine that has been machine graded.

The machine stress grading process requires that quality checks be built into the operation of the machine so that its grading is uniform over time, and that the correlation between grading parameter and the properties of the product remains valid. These checks are on the performance of the machine, which can be found by running calibration sticks of known properties through the machine, and on the performance of the output, by periodically performing destructive tests on samples of the graded timber.

In-grade properties also need to be verified from time to time.

In setting up a grading machine, some in-grade testing is necessary to establish the correlation between the grading parameter (minor axis E) and the other properties, establishing threshold grading machine values to separate grades.

The reliability of structural design properties used by a structural designer is linked to the type and effectiveness of the grading operation. Quality control gives some indication of the success of the grading, so it is incorporated in the design of timber elements. This level of quality control is necessary to ensure continued reliability in the sorted product.

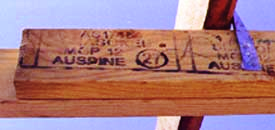

Grade mark

A grade stamp is applied at the tail end of a machine stress grading process. The machine sorts the timber on the basis of its calibration and the measurements made on each length of timber. The final step is the placement of a grade stamp which will enable all subsequent people in the marketing, distribution and delivery chain to recognise the length of timber as one which has properties described by the marked grade.

Some grading machines also have markings that run the length of each graded piece of timber. For MGP grades, it is the printed mark on the length that indicates the grade of the whole piece. For some machines, this is the coloured ink or paint mark, and for others, it is a laser-printed mark at regular intervals.