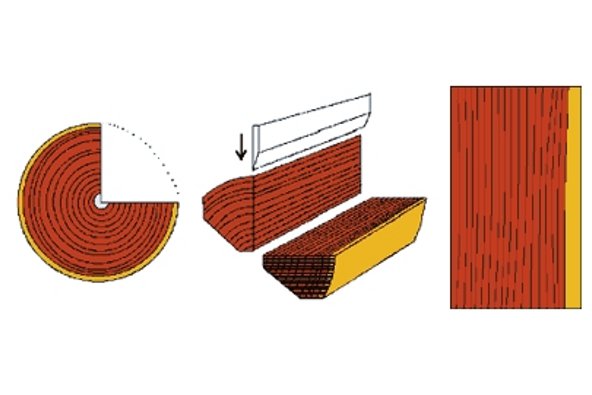

Decorative wood veneers are produced by either slicing or peeling a much larger piece of timber log into thin slices or veneers. The way the veneer is cut will determine the appearance of the grain.

Crown

Veneer cut from this part of the log produce leaves with crown pattern with some straight grain either side. As the crown cut moves through the log towards the centre, the leaves become wider with the crown being narrower and more well defined, with wider straight grain sections on either side. A crown cut shows the true grain of the timber.

Quarter (false)

The veneer produced is generally straight grain material, often with a slight swing where the faulty part of the heart of the log has been removed.

Quarter (true)

Leaves cut in this method produce fairly straight (parallel growth rings) grain patterns.

Rotary

Veneer produced by this method has a non-descript swirl pattern. This type of veneer is produced by peeling a log which has been centred on a lathe.

Other veneer patterns include:

- Birdseye - figure in veneer exhibiting numerous rounded areas resembling small eyes.

- Quilted - blistered appearance shimmering scalloped pattern.

- Pommele - a scalloped figure, most usually found in mahogany.

- Burls/Burr - abnormal growth producing tightly packed buds and knots producing highly decorative veneer that mostly appear as rings and dots.

- Figured - the markings, often forming wavy shimmering patterns, these may be regular or irregular ranging from fiddleback to block figure.

Jointing veneers

The veneer leaf - or flitches, as bundles of sliced veneer are known- is then clipped to size before being jointed into usable sized sheets called layons. Veneers can be jointed by stitching, splicing or using paper tape. Stitching and splicing are the most common methods and are generally produced by automated machinery.

See ‘Appearance Grades' for more details on matching patterns available when jointing veneers.

Bonding veneers

Pressing is the process of binding veneer layons to a substrate using specialised pressing equipment, which generally applies heat and pressure. Suitable substrates such as MDF, particleboard and plywood would generally not be appearance-grade quality and as such don't have an attractive grain or figure, making them perfect for use with the decorative veneer. Most manufacturers will supply bonded veneers trimmed and sanded.

Aside from decorative timber, timber veneers can also be joined together to create LVL and plywood. Veneer for structural applications is generally peeled.

Benefits of decorative veneer

The finished decorative veneer product will give the illusion that it is one solid piece of wood, as per the species of the face veneer. This is desirable for a number of reasons. Firstly, it provides an economical way to use timber resources, or those species that may be rare or more expensive. Secondly it means you can get the appearance benefit of certain species that may have otherwise been impractical to use for the application, ie using a solid piece of timber may not have been possible as per certain hardwood species.

Decorative veneers may also prove to be a more stable material than using a solid wood equivalent. This means that decorative veneers provide one of the most economical and sustainable applications of timber.

A further benefit of using decorative veneers is the extensive range of colours and styles available - just about any species of wood can be turned into a veneer. This provides endless opportunities for architectural applications.

Other veneered products include laminated veneers edging, profile wrapping and decorative inlays, including marquetry.

Joinery

Panelling, Interior

Allied Forest Products

ALLKIND Joinery

Australian Timber

Briggs Veneers Pty Ltd

Britton Timbers

Cedar Windows Pty. Ltd.

Dekhar Outdoors

Fewings Joinery Pty Ltd

HYDROWOOD

Logicoat

Matilda Veneer

Nannup Timber Processing

Simmonds