Overview

The serendipitous event that would ultimately decide the primary structural frame for what became a 930m2 collection of wood and glass pavilions, followed a major storm in 2000 which broke up the submerged hull of a ship that had run aground in fog some 80 years earlier.

The 'treasure' released from the ocean floor included a consignment of milled Douglas fir logs - some more than 12m long and in near-perfect condition. Architects Miller Hull had recently received a brief for a residence on Bainbridge Island that asked for "a lot of wood" to be used, so they quickly alerted their client to the bonus from the deep.

The salvaged logs were in prime condition, prompting the architects to design the entire structure around them.

In a separate piece of good fortune, the client found a giant cedar stump about 10 m high and 3 m in diameter, which produced "unbelievably beautiful" timber with extremely tight vertical grain and not a knot anywhere. It produced enough wood to do the entire house in custom patterned t&g siding.

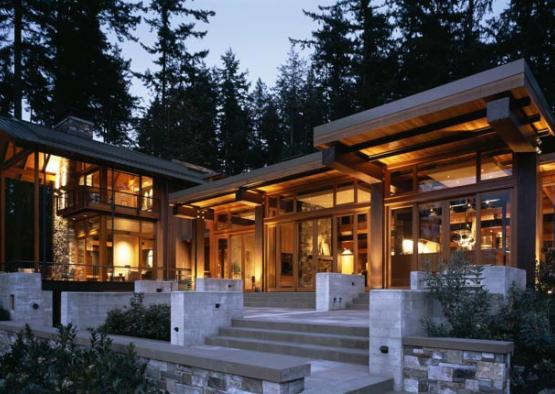

The final plan choreographs the three natural landscapes inherent within the site: a low meadow, an old growth forest, and a steep bluff overlooking Puget Sound and the Olympic Mountains.

Case Study courtesy of timber+DESIGN international magazine.

Structure

The main residence has three wings. The low metal roof and stepping-stone walls screen the larger wings and tenuously connect the north wing, main pavilion and the south wing. Interruptions in the flow roof and stone walls create understated entrance foyers and courtyards.

Each wing is developed to suit the rooms it houses, their asymmetric gable roof forms bracketing the main pavilion between them. To satisfy the clients' desire for a hot tub off the master bedroom, a trestle bridge in Alaskan yellow cedar was built 4.2 m above the ground to a platform in the trees.

After two years drying, the salvaged Douglas fir was milled to 500 x 500 mm and, with wood-framed bearing walls, forms the primary structural frame. Structural steel is also used in limited areas. Floor framing is dimensional or engineered lumber with plywood sheathing.

There are three roof framing systems: glulam wood purlins and 50 x 150 mm car decking used at the gable form roofs at each end of the house; T-shaped steel purlins bearing on the top of the salvaged timber frame, with car decking over the steel T's; and dimensional lumber framing members and car decking for storage areas and the water tower. Interior partitioning is standard wood-framed construction throughout.

Exterior

Vertical, gable-formed sections and the storage building are sided with the salvaged cedar - milled into custom 300 mm boards with kerfed backs and special bevel joint detailing on all four edges. The technique provides a clear, vertical grain finish, with a tightness and consistency of grain the architects describe as that is "breathtakingly beautiful".

To achieve a lower profile on the centre of the house, a horizontal siding system was developed, using the western red cedar and Alaskan yellow cedar as the accent.

Extra pieces of the salvaged timbers were used as light totems at the entrance to the house. Behind is a storage building, clad in the vertical cedar siding to match the house. Exposed wood surfaces were Sikkens stained, with a latex stain inside.

Cherry and Douglas fir panels are used throughout the interior. Most ceilings are exposed car decking, with 'clouds' of drywall floated below for light fixtures. Wood flooring throughout the kitchen, family, dining, and living rooms is machiche (Caribbean cherry).