Pingelly WA 6308

Australia

Overview

The building was designed with longevity and sustainability at the forefront, given the scarce resources available to the isolated region. Materiality, particularly transportation of materials, was an essential focus. The structure was a co-design between Patrick Beale at ATC studio (University of WA), and Iredale Pedersen Hook.

-32.5327744, 117.0840707

Structure

The facility at Pingelly is built from a unique and innovative timber box frame, that was prefabricated off site.

The benefit of a prefabricated timber build is the ability to CNC joints into the system, to allow for accuracy and joinery that are impossible for hand made construction. LVL joists are dovetail mortise and tenon jointed into the LVL bearers, in a co-planar format. The subfloor is 21mm sructural plywood.

The structural wall frame utilises an LVL box construction in the sports hall and function centres. In the ancillary buildings, the structural frame is all The LVL prefabricated frames are assembled on site for both upper and lower wall sections. The elements are assembled in panels and lifted into position between structural bays.

Rafters are LVL Box construction in the main sports hall, providing extremely rigid connections for the large span . An LVL truss assembly was used in the function centre. An LVL engineered frame was used on smaller ancillary structures. The purlins are LVL I-Joists in the sports hall and function centre, whereas engineered LVL assemblies make up the roof cassettes on the smaller structures.

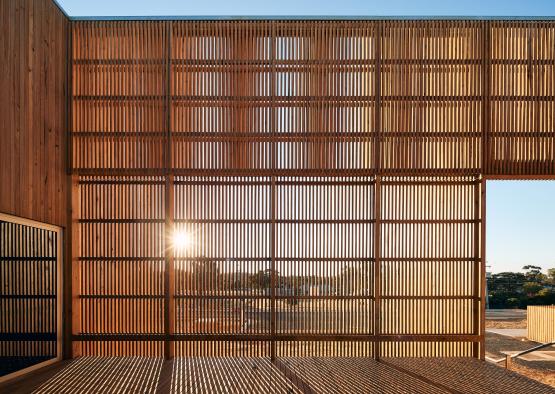

Exterior

External cladding for the centre is plantation grown yellow stringy bark [Eucalyptus muelleriana], in 19mm and in 35mm formats depending on exposure to the elements. The material was grown locally, providing a vast resource to a town that has limited access to building resources. Locally sourced timber also requires less transport, and therefore less emissions in it’s LCA.

The external cladding of the building is protected wherever possible with broad verandas that shield the majority of the timber from adverse weather conditions. Where the timber cladding is exposed to the weather, a 35mm thick section is used to allow a layer of sacrificial degradation to occur without risking the integrity of the building.

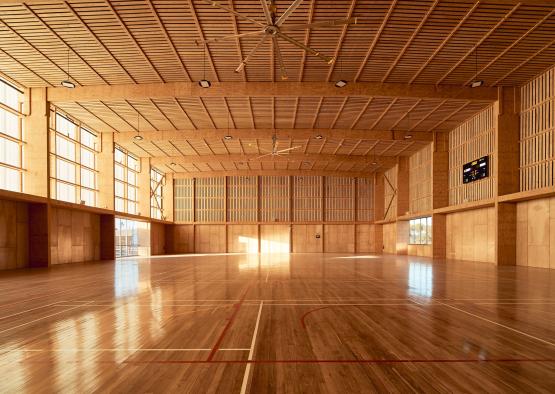

Interior

For the floor finishes, yellow stringy bark (Eucalyptus muelleriana) was used over a structural plywood base.

Huon Pine veneered plywood was used as the lower wall lining in the sports hall, with pine boards assembled in cassettes for upper walls and ceilings. For the function centre, yellow stringy bark T&G wall paneling was used.

In the bar and cultural hall, the wall paneling is recycled Jarrah from the previous structure on the site- about 10% of the overall lining.. Ceilings in the bar and function centre are YSB, pre-assembled cassettes.

A small amount of gyprock was also used for lining.