141 Mon Repos Road

Mon Repos QLD 4670

Australia

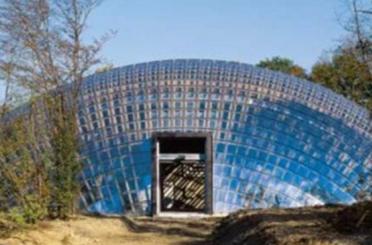

Overview

Mon Repos Turtle Centre occupies a sensitive beachside location in a Central Queensland conservation park. The project was envisaged as a complex, but hardy timber frame that celebrated local materials.

-24.8020407, 152.4427077

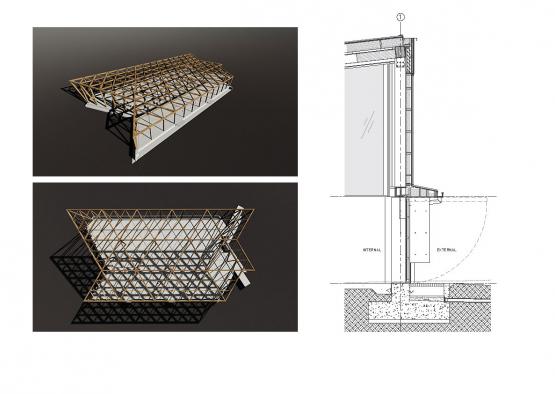

Structure

Timber was specified not only for its beauty or close local production, but for its durability in the corrosive coastal environment. The brief stipulated a 50-year design life, and the architects decided that timber would likely outperform steel over this time period, and be available for reuse at the end of its life.

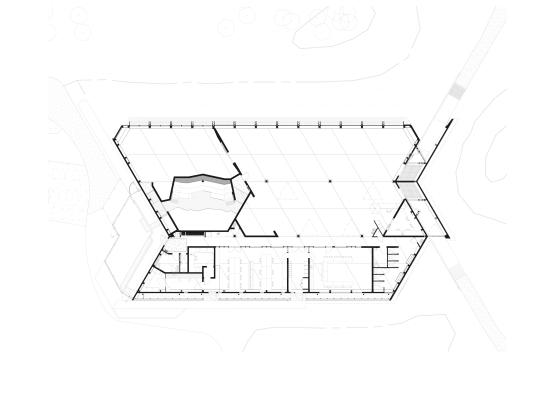

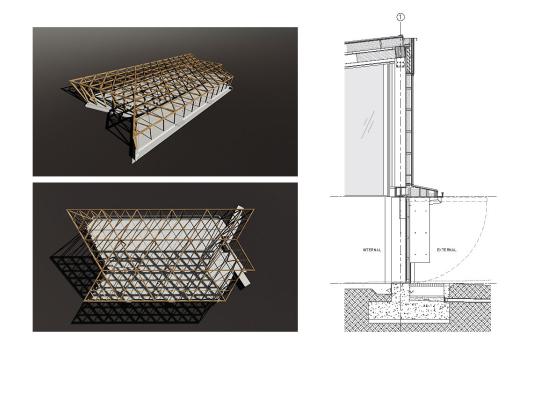

The overarching structure for the Mon Repos Turtle Centre is a timber glulam post and beam grid. The grid is arranged as a diagrid- which is essentially a diagonal grid that produces a diamond shaped structure. The posts and beams have been engineered from laminated strips of spotted gum, which is a Class 2 hardwood, so performs excellently outside. The spotted gum was sourced from Central Queensland – the harvesting and procurement was undertaken early in the design process to ensure adequate supply.

The diagrid is a 9.6M x 9.6M grid, which allows for standard sheeting to fit between the members with no wastage. Not only was this type of structural grid found to be the most efficient for reducing material use, but the diagonal frame also increased the buildings lateral bracing.

One of the main benefits of glulam, besides its strength, is its inherent material efficiency. The engineered product doesn’t rely on large lengths of timber to produce large overall members. Instead, it uses smaller sections that may have been previously discarded to make larger members from composite elements glued together. Transportation to the site was also minimised through the ability to stack the timber members in single lengths.

The fabrication of the entire timber superstructure was undertaken in Maryborough, which is less than 2 hours away from the building site at Bargara. Prefabrication was an early decision, which meant all the consultants could be clear on major decisions early. Shop drawings, and the supply and fabrication of the structure, were all tendered as an early works package. This meant that the entire timber structure was fabricated and ready for site installation before the main contractor was appointed. It is highly unusual for a public project to undertake such a novel approach to the procurement aspects, but also one of the great innovations of the project.

Exterior

Externally the building is wrapped in both copper and recycled tallowwood cladding. The copper wraps the upper half of the exterior, while the tallowwood provides the human scale cladding- where tactility and warmth is key.

The visual quality and durability of the recycled Tallowwood was why it was chosen. The recycled timber complements the copper claddings hue, as well as that of the spotted gum superstructure. The combination creates a harmonious material palette that will patina gracefully over its lifetime.

The tallowwood was placed at a setback to the copper clad half of the building, protecting the timber from sun and weather, which will extend its life. When specified properly like this, timber is an extremely resilient and low maintenance building material.

Marine plywood panelling was also used on the exterior for public event spaces. The robust and corrosive resistant material is suitable for a high use, public space, as it contains exterior grade glues and higher quality plys. The plywood was prefinished with a dark stain when delivered to site.

Interior

Internally, plywood linings were used for most of the spaces. The diagrid structure elements were designed to be multiples of standard sheets wide to eliminate wastage from offcuts. The sheets were then screwed on instead of nailing, allowing for ease of deconstruction and reuse.

Passive measures such as naturally ventilated spaces and daylighting strategies were designed into the building to reduce reliance upon energy intensive man made systems. The largest space in the building is entirely naturally ventilated and lit only from a series of triangular skylights.

The diagrid roof structure was another example of waste minimisation through design. The diamond structure was infilled with triangular plywood ceiling panels. These were designed and detailed to be cut from a single 2.7m x 1.2m plywood sheet, cut into multiple triangles to fit snuggly into the structural opening.