Overview

A versatile office complex, the IZM Tower is carbon neutral and built with regional resources. The project focuses on resource efficiency in materials, energy, techniques and site management. The wood and hybrid wood/concrete construction makes the weight of the building and its resource impact less than half of what it would have been had construction been conventional.

Expertise, equipment and resources are locally available in the Voralberg region: the structural needle wood is harvested locally and the oak wood for interior fitting and exterior cladding is of regional extraction. In all, some 3000 m3 of wood have been used for this building, corresponding to two days’ forest growth in the region.

While a prototype tower was still under construction, the IZM tower project was won by the consortium in an international design and build competition that led to the implementation of the hybrid building system in a real life turnkey project. The construction was completed in less than sixteen months.

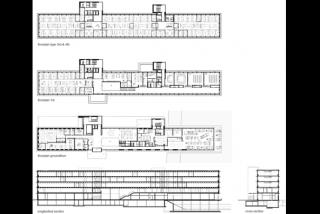

The centre provides offices for 270 staff in multiple arrangements, a staff restaurant, an information centre for the general public, training facilities and conference rooms.

From the 1st floor up, the process is a dry construction as in the prototype LCT: no formwork, no water, no drying out, no long-term scaffolding, no storage on site. Prefabrication also takes most imponderables out of site construction.

The Austrian society for sustainable real estate certified the completed building in the highest category environmentally.

Images : Cree GmbH, Hermann Kaufmann ZT, Norman A. Müller

In service since August 2013

Structure

The four upper floors are built from prefabricated wood and wood/concrete elements with airtight façades and roofing. Only the basements, the piles set into the lake, both ground and first level floor and the two blocs of lift shaft and stairwells are in reinforced concrete.

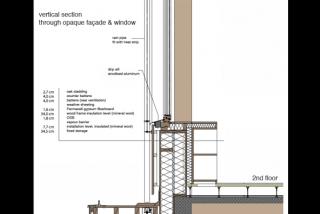

The insulated façade elements (46cm deep) are prefabricated in sets, combined with the floor high peripheral glulam posts, the peripheral counterparts of the lift and stairwell blocs, the axial combined steel and concrete posts and the central steel girder that runs the length of the building on each floor. Each set is delivered as one piece to the building site and installed as a whole.

The façades usually come complete with windows, but in this case the window blocs were fit on site. This did not majorly effect the construction time. The single window-blocs were put into place sequentially, so that each floor was closed to the elements before the next floor was assembled.

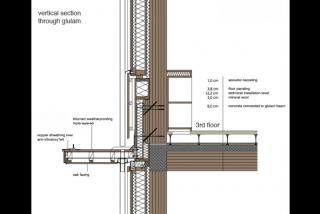

The glulam posts and the central steel girder are fitted with vertical steel pins that fit into reservations in each corner of the floor slabs. These slabs are formed so that the peripheral load of the building's upper floors is carried through each slab's outer concrete lip.

After geometrical correction, the play necessary for easy assembly on site is filled in with a special fast-setting resin mortar. This joint, together with a sprinkler system, ascertains that each floor functions as one single horizontal fire section.

Exterior

The exterior cladding is made from regional oak with protective copper sheathing.

The running awning provides protection from blinding sun and overheating in summer as well as from windswept rain. It is designed to allow exterior window cleaning and is equipped with life-lines.

Interior

All fixed furniture, partition facing and parquet are made from local and regional oak.

Suspended soundproofing and ceiling battens are from a local pine wood, white fir.